The beer didn’t come in cans or bottles for summer interns at area breweries. By the time the beer reached their hands, test tubes and beakers were the likelier containers.

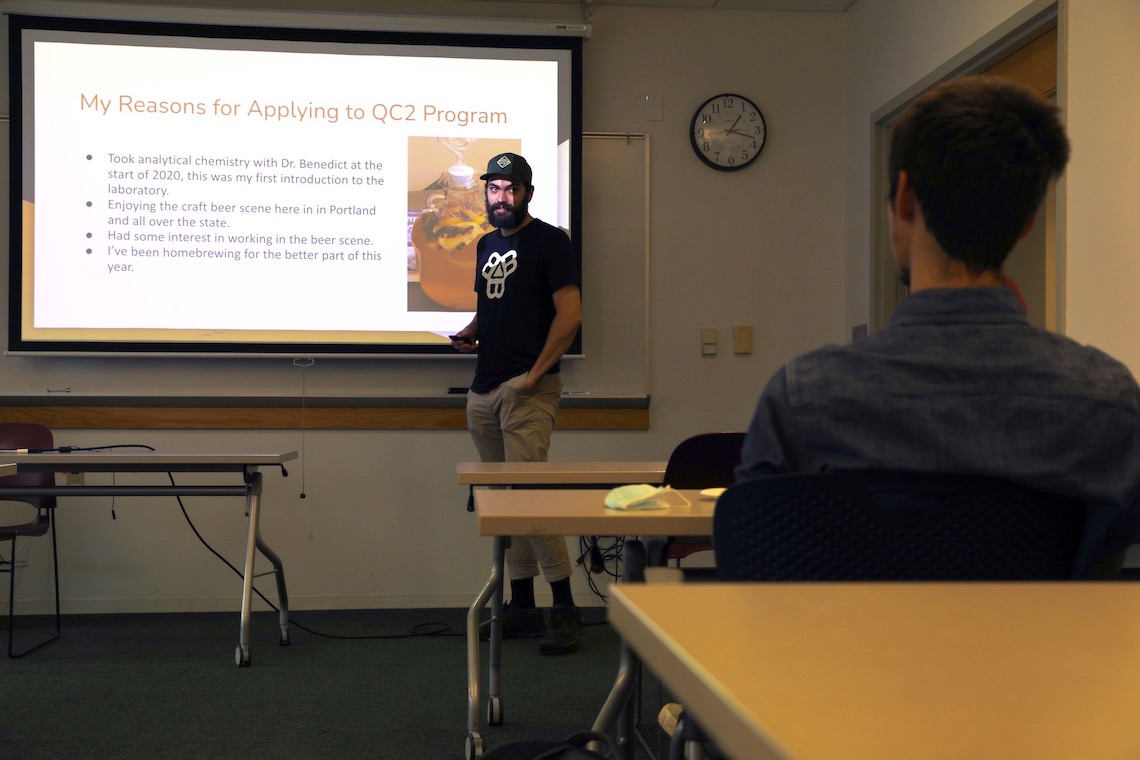

The latest session of the internship program run by the Quality Control Collaboratory (QC2 Lab) ended on August 17 with a series of presentations at the Wishcamper Center in Portland. Each of the four interns had about 15 minutes to explain their work and answer questions from the industry leaders, educators, and peers who came to hear them.

“I think they got a lot out of the experience,” said Dr. Lucille Benedict, Director of the QC2 Lab. “It’s fun to see them applying their science that I know they’ve learned here . . . and seeing how much of that science is embedded in brewing.”

The QC2 Lab provides students with instruction and resources to scientifically analyze craft beer. A partnership with the Maine Brewers Guild ensures a steady supply of beer samples in exchange for test results to improve the product.

Students don’t need to be planning on a career in the beer industry in order to participate in the QC2 Lab. It’s open to anyone with a strong science background. The goal is to help students broaden their professional options into jobs they may not have previously considered.

Bryant Hall is heading into his fifth year of study in the fields of Human Biology and Biochemistry. That background served him well in the lab at Bissell Brothers Brewing. Hall was the first intern to speak. His presentation focused heavily on his study into the effects of polyphenol levels on the shelf life of beer, especially New England-style IPAs.

“It really prepares me for working in a lab, being very consistent, especially in a production-focused industry,” Hall said.

Bissell’s Quality Manager, Matt Nelson, sat in on the presentation. He and Hall worked closely together throughout the internship. Nelson liked that Hall was different from a lot of recent job applicants he’d seen. Many of them left college with a knowledge of scientific principles but hadn’t learned how to apply their studies in a real-world setting.

“Just to see how much lab skills he’s able to gain from QC2 and from USM really made me much more likely to work with him in the future because they’re encouraging that sort of practical lab ability that we need so much right now,” Nelson said.

The way that Nelson and Hall hit it off was no accident. By the time the summer internships began in May, QC2 leaders had already done months of research to make a good match between students and hosts.

“I think the biggest thing for me was hearing from all the brewers as to how much value our interns added. I think that was probably the biggest surprise to them too,” said Benedict.

Even students who are too young to drink beer can still make valuable industry contributions. Trevor Grenier was 19 years old when he began interning with Geary Brewing Company at the end of his freshman year. Geary doesn’t have its own lab for beer testing. In his presentation, Grenier talked about using his Biochemistry background to create a plan to build a lab.

Nicole Savoy is at the opposite end of her undergraduate career as she heads into her senior year of studying Biochemistry. Her job at Austin Street Brewery was to test for bacterial contaminants, but she went beyond collecting data to suggest a solution. Her presentation described how she used an alcohol lamp to create an updraft for sterilization. The idea came to her from her classroom work with Bunsen burners that operate much the same way.

The QC2 Lab sets up its interns to succeed by recommending they have at least a basic understanding of chemistry and biology. From that foundation, QC2 instructors put interns through a two-week boot camp in microbiology, advanced chemistry, and brewing. Only then are they ready to join their hosts.

“Fostering a relationship with the university and the community is really great, all positive,” said Merritt Waldron, Director of Quality at Baxter Brewing Co.

Haylee Duval brought an additional skill set to her internship at Baxter. Along with three years of study in Human Biology, she also worked as a bartender for several years. Her ultimate goal is a career in medicine. Duval plan to follow up her brewery internship by going to work in a research lab at Maine Medical Center to study multiple myeloma.

“I know that I’ll encounter a lot of lab work,” Duval said. “Getting familiarized with a lot of the equipment and the procedures, whether I’m working with beer or blood, you run a lot of the same tests.”

Her tests on dissolved oxygen values in Baxter’s beer were a centerpiece of her presentation. Too much oxygen in beer limits its shelf life. Duval established an upper control limit of oxygen levels to help set a standard for freshness.

Having proven she could handle her main duties, Duval welcomed additional side projects. A flavor trial had her combine a batch of beer with Froot Loops breakfast cereal to see how they would interact.

Beyond the lab, Duval’s internship also gave her a window into office culture. A conversation with Baxter President Jenn Lever over lunch made a big impression.

“We just talked about some of the challenges that she’s faced in a male-dominated industry and how she’s dealt with them,” Duval said. “That gave me some good advice as I move forward.”

Creating those kinds of opportunities for all of the interns can be expensive. Funding comes from the Maine Economic Improvement Fund (MEIF), which provides financial support for research projects through the University of Maine System.

The return on that investment was on display in each of the presentations. Participation in the program doubled from two to four interns since last summer. As long as funding and interest remains strong, QC2 leaders are hopeful the program can continue to grow.